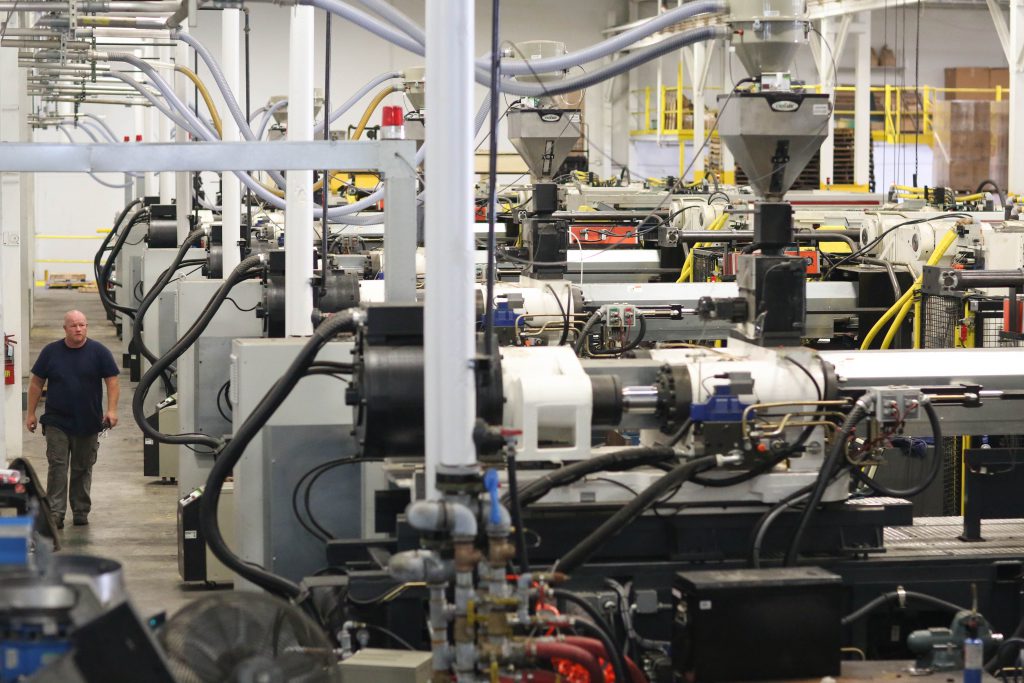

ISO 9001:2015 is evident the minute you walk into our state of the art facilities. The physical layout of our plants leaves no room for costly, wasted production time. Dinesol Plastics has two facilities spreading over 500,000 square feet which operate 24 hours a day, 7 days a week. The wide range of presses, materials processed and secondary operations allow us to provide a one stop shop for all your injection molding needs. To ensure our partners continue to lead their markets in this world economy, Dinesol is continually evaluating and expanding our technology base. Future expansions, plant redundancy and ultramodern equipment make our investment your investment into the future.

Capabilities

- High pressure injection molding

- Rotary 2 shot injection molding

- Gas assist injection molding

- Insert molding

- Injection over molding

Features

- 50 presses ranging from 110 through 3000 ton of clamping force

- Barrel capacities from 8 oz. through 607 oz.

- Magnetic Platens

- 20 silos with storage capacity exceeding 1,500,000 lbs.

- 14 railcar and bulk truck unloading stations

- Automated handling systems

- 7 axis articulating robots

- At the press volumetric blending

- Central drying system 12,000 lbs./hr.

- Automated handling systems

- Avalon imaging systems

- Central chilling systems

- Overhead cranes 10 to 40 tons

- Production serialization and part specific traceability

Experienced in Molding

- Commodity Resins:

- PP, PS, HDPE, LLDPE, LDPE

- Engineering Resins:

- ABS, ASA, Acetal, Nylon, Polycarbonate, PPS, PPE

- Specialty Blends:

- Glass, Glass/Material Blends, ASA Blends,

- Wood Flow Blend, Structural Foam

Secondary Operations

- Assembly

- Packaging

- Shrink Film

- Laser Etching

- Hot Stamping

- Pad Printing

- Silk Screening

- Coditherm

- Hot Plate Welding

- Vibrating Welding

- Heat Staking

- Ultra Sonic Welding

- Solvent Bonding

- Hot Melt Gluing Assembly

- Insert Molding

- Inmold Labeling

Warehousing and Logistics

- Manage 200,000 sq. ft. warehouse

- 12 shipping and receiving docks

- Logistics scheduling system to handle your most demanding delivery schedule

- Flexible stocking programs